Electrode Machining

Our Services

High-Precision Electrode Machining Services

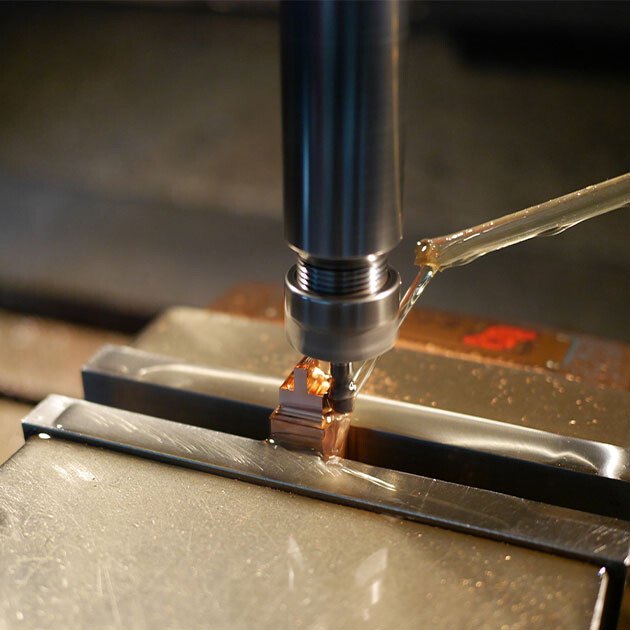

For complex contours, deep grooves, sharp corners, or special textures that are difficult to machine with traditional CNC milling, we utilize high-precision Electrical Discharge Machining (EDM) technology. Through precisely fabricated copper electrodes, we use electrical discharge erosion to achieve exceptionally fine forming effects on hardened mold steel, perfectly rendering every design detail of the product.

Complex Geometry Forming

Capable of machining complex geometric shapes that are impossible to achieve with conventional tools, such as deep grooves and thin-rib structures.

Expert in Micro Details

We specialize in the forming of precise details such as micro-holes, thin ribs, and sharp internal corners.

Diverse Electrode Materials

Based on different machining requirements and cost considerations, we offer a variety of electrode material options, including copper.

Four Steps from Concept to Completion

01

File Analysis & Consultation

The client provides the 3D files for machining, and our engineers conduct a feasibility analysis to discuss the optimal machining plan with you.

02

Electrode Design & Programming

Based on the machining requirements, our team designs the electrodes, breaks them down for manufacturing, and completes the programming for both CNC and EDM processes.

03

Electrode Fabrication & Discharge

First, we fabricate the high-precision physical electrodes. They are then installed on the EDM machine to perform precision electrical discharge machining on the mold steel.

04

Inspection & Delivery

After machining, we use precision instruments like a Coordinate Measuring Machine (CMM) for dimensional inspection. The product is delivered once we confirm it meets all drawing requirements.