Office Furniture Manufacturing

Our Services

Professional OA Office Furniture OEM Services

OA office furniture manufacturing has been the foundation on which ZOWELL was built. With decades of experience and a robust supply chain, we offer comprehensive OEM/ODM services—from component production to final assembly. We are your trusted partner for delivering top-quality, cost-efficient solutions.

Structural Design & Optimization

Based on your design, we provide a professional Design for Manufacturability (DFM) analysis to optimize the product structure, enhancing cost-effectiveness while maintaining quality.

Multi-Material Processing

We are familiar with the processing characteristics of various materials commonly used in office furniture—including metal, plastic, and wood—enabling us to meet your diverse product needs.

Precision Metal Fabrication

We offer metal tube bending, stamping, welding, and polishing services to produce sturdy, durable metal frames for office desks and chairs.

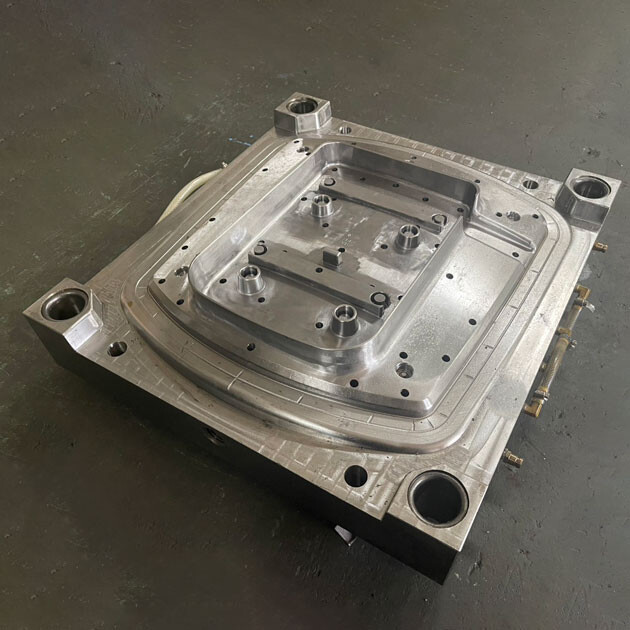

Plastic Part Injection Molding

With our in-house mold technology and injection production lines, we can manufacture a wide range of high-quality plastic components, including armrests, casters, and backrests.

Surface Treatment & Finishing

We offer various surface treatment options, including powder coating, liquid painting, and electroplating, to ensure a beautiful, rust-proof, and durable finish.

Final Assembly & Packaging

We offer efficient final assembly, rigorous quality inspection, and customized packaging services—so your products are delivered in optimal condition.

Our Design & Development Process

01

Design Review & Consultation

Upon receiving the client’s product design drawings, we conduct a Design for Manufacturability (DFM) analysis and offer professional advice on materials, manufacturing processes, and cost structure.

02

Mold Development & Quotation

Based on the confirmed design, we develop the production mold and provide a detailed quotation that includes both tooling fees and per-unit product costs.

03

Mass Production & Quality Control

After the mold is completed, we proceed with a first article inspection. Upon approval, we commence mass production and implement strict quality control throughout the process.

04

Assembly, Packaging & Delivery

We provide final product assembly and customized packaging services, delivering the high-quality finished products safely and on time, according to the client’s specifications.