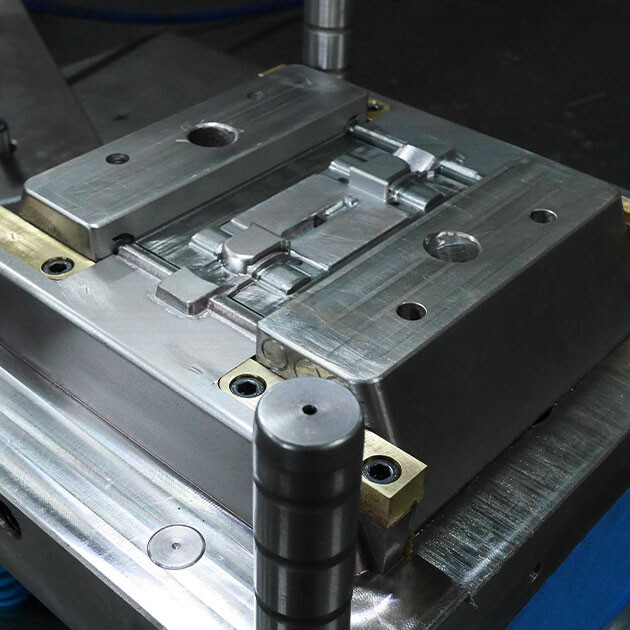

Mold Assembly

Our Services

Precision Mold Assembly Services

Mold assembly is a critical step in ensuring a mold functions correctly. Our assembly process is carried out by experienced senior technicians who, with immense patience and precision, perfectly fit together anywhere from dozens to hundreds of intricate components. They also conduct rigorous mechanical action tests to ensure that every mold dispatched from ZOWELL operates smoothly and flawlessly.

Senior Technician Team

Our assembly work is handled by senior technicians with over ten years of experience, ensuring every detail meets the highest craftsmanship standards.

Strict Tolerance Control

During the assembly process, we strictly control and fine-tune the fitting tolerances of all components to ensure the precision of mechanical movements.

Smoothness Testing

After assembly is complete, all moving mechanisms such as sliders and ejector pins are repeatedly tested to ensure their movements are smooth and unobstructed.

Detailed Assembly Records

We create detailed assembly and calibration records for every mold, facilitating future tracking and maintenance.

Water Circuit Testing

The mold’s cooling water circuits are tested to ensure there are absolutely no leaks, which is crucial for stable temperature control during mass production.

Ejection System Calibration

We precisely calibrate the ejection system, including ejector pins and blocks, to ensure the finished product can be demolded smoothly and without damage, improving the production yield rate.

Our Mold Assembly Process

01

Component Check & Preparation

Before assembly, all machined mold components undergo a final dimensional inspection, cleaning, and sorting to ensure everything is fully prepared.

02

Core Mechanism Assembly

Our senior technicians begin the assembly and initial calibration of core mechanisms such as the mold core, mold base, sliders, and lifters.

03

Peripheral System Installation

We then install peripheral systems like the cooling water circuits, ejection system, and guiding mechanism, ensuring all channels and linkages are clear and unobstructed.

04

Final Calibration & Testing

We perform comprehensive tests for the smoothness of mechanical movements and air tightness. Upon completion, the mold is handed over to the mold trial stage.